Boks Stol (2019)

(Danish for "box chair")

(Danish for "box chair")

While studying furniture design in Copenhagen, I designed and built this chair that disassembles into a portable box.

My goal was to create a chair with the qualities of a good friend; it should be honest, approachable, friendly, adaptable, and communicative. For all that to be true, a person's relationship with the chair would have to involve more than indifferent sitting. I wanted to design around a more intimate and interesting connection with the object.

My first priority was ergonomic proportions, measurements, and angles. Though my process was completely physical, I designed this chair parametrically. Once I established the angle of the back and the seat's depth and height from the floor, I designed the parts around those measurements. Every number trickled down from the initial constraints.

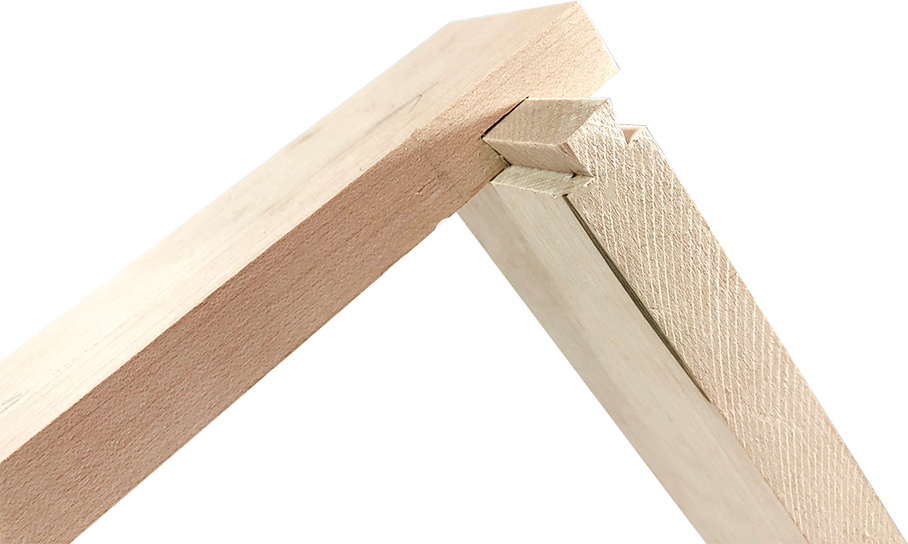

The final chair contains no metal.

It is made with maple, birch, glue, and leather.

It is made with maple, birch, glue, and leather.

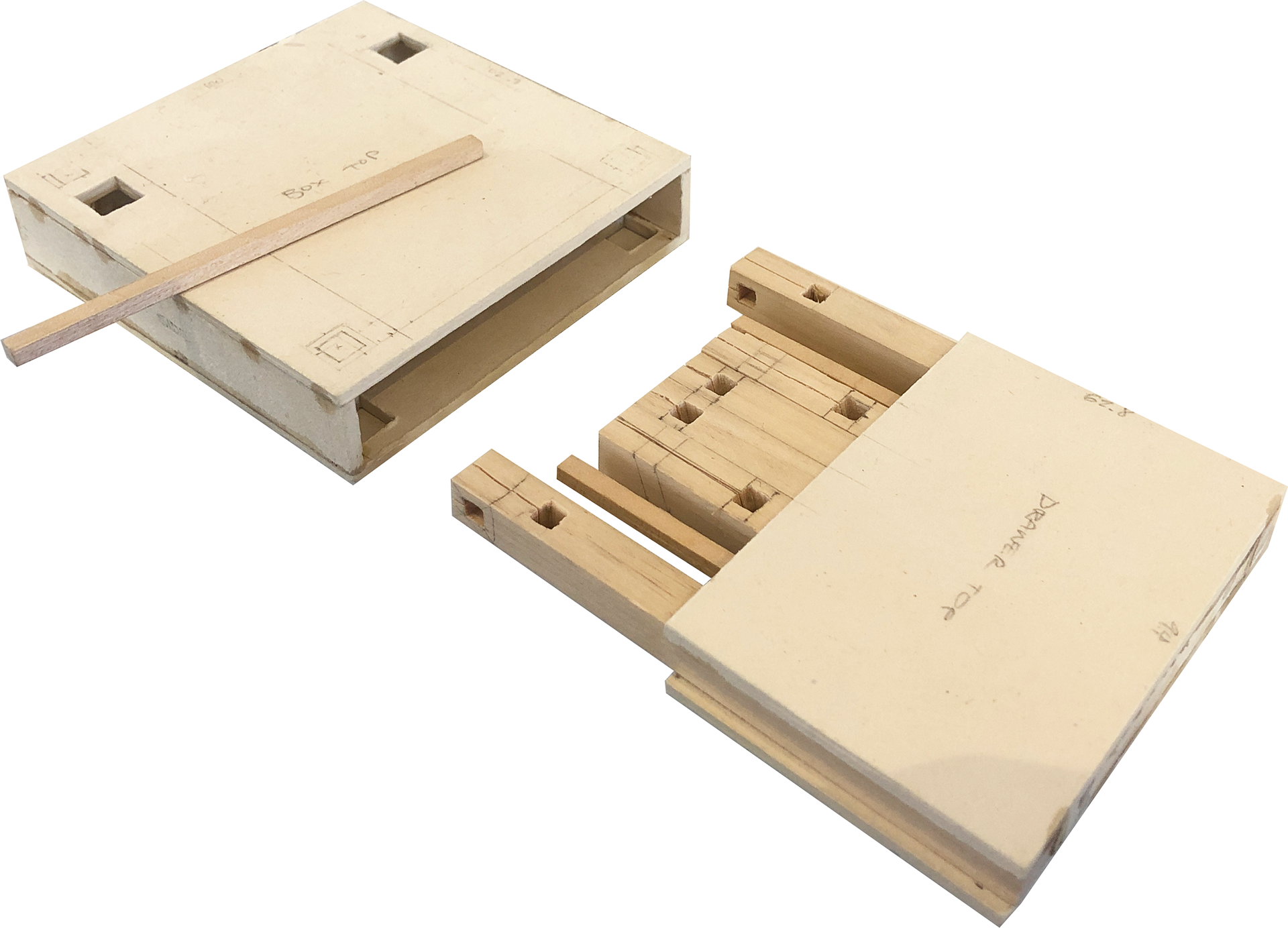

Model 1

Model 3

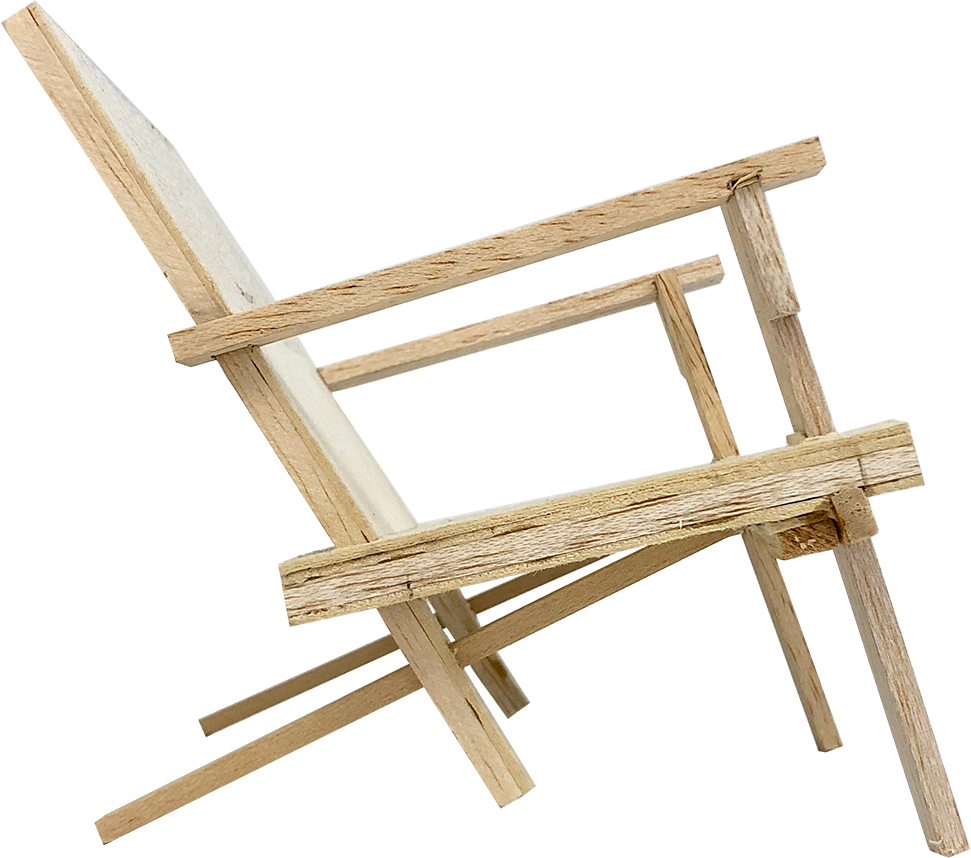

Construction

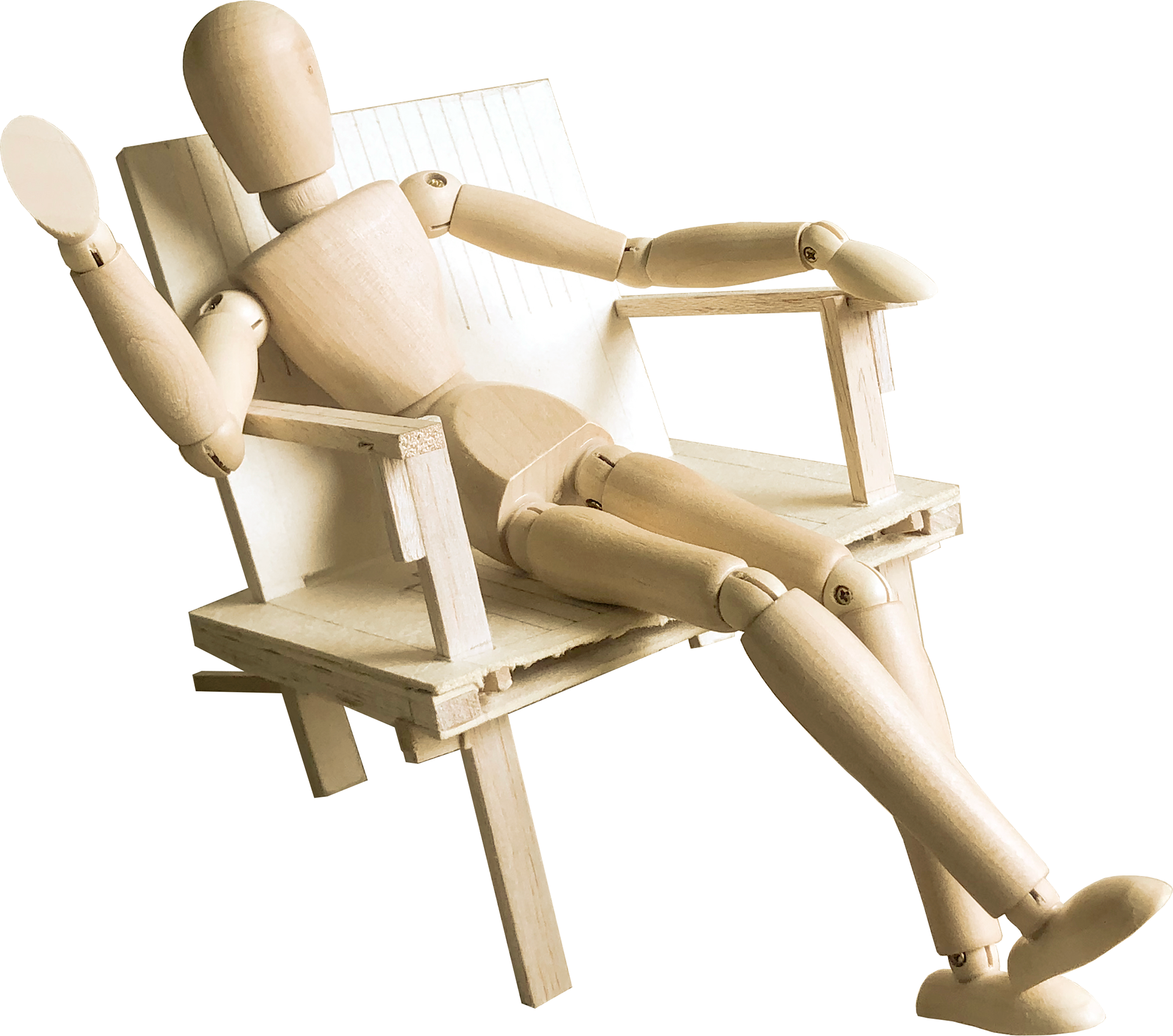

Final Product

In Copenhagen, I walked for over an hour with the Boks Stol at my side and finally settled by a lake with my friends to have a celebratory beer and say goodbye. It was a wonderful punctuation mark on my summer.

Following this first iteration, I am certain that modern technologies like Solidworks and a CNC router will perfectly compliment the logic that I have built into the design. I hope to make the chair lighter and experiment with other locking/carrying methods. I will also continue experimenting with the integration of slats to provide comfort.

2019

...

Lounge Box (2020)

Back in Pittsburgh, I set out to improve the chair. As planned above, I aimed to design a more comfortable chair, utilizing the flexibility of plywood for slats in the seat and back. I decided to make an armchair, to fully embrace the goal of comfort. Of course, it would still have to collapse into a box.

Back in Pittsburgh, I set out to improve the chair. As planned above, I aimed to design a more comfortable chair, utilizing the flexibility of plywood for slats in the seat and back. I decided to make an armchair, to fully embrace the goal of comfort. Of course, it would still have to collapse into a box.

My final product, as seen to the left, was born largely through time-intensive handwork. Though I designed the chair in Solidworks and cut the plywood pieces with a CNC router, I spent weeks chiseling diagonal holes into the plywood at precise angles. This process highlighted manufacturing considerations that I'd like to optimize. Once all of the holes were finally done, cutting and fitting the interfacing rectilinear parts went smoothly.

Model 1

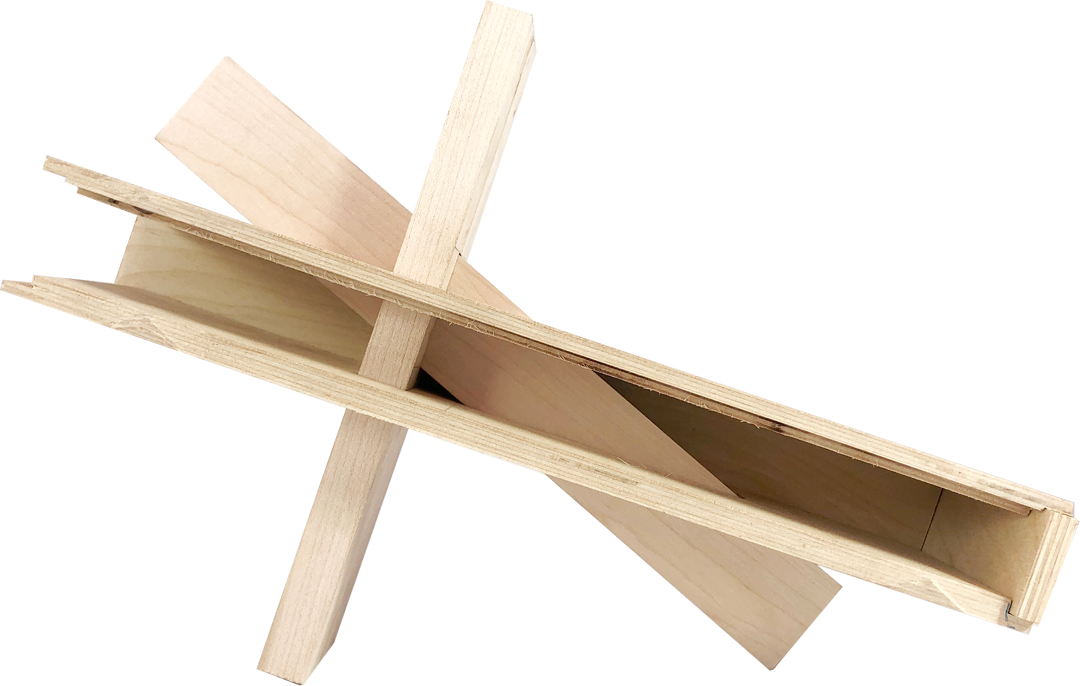

Plywood Flexibility Experiments

Solidworks Model

Joinery Models

Construction

Final Product

On the right, you can see the Boks Stol and Lounge Box together on Flagstaff Hill, in Pittsburgh PA.

Moving forward, I intend to make the chair lighter by further optimizing proportions and eliminating excess material, experiment further with carrying methods, and further optimize the manufacturing process.